Complete solution for thermal processing in the food industry

Providing the right machines for thermal treatment is only part of our service. We offer a complete package of services. We ensure that processing your products is worry-free. Providing peace of mind is our motto. Minimising downtime and avoiding high costs.

Experienced Workers

Experienced Workers Take Care Clients Satisfaction

Take Care Clients Satisfaction Globally Stable Partner

Globally Stable Partner

Creating an adequate solution for your company

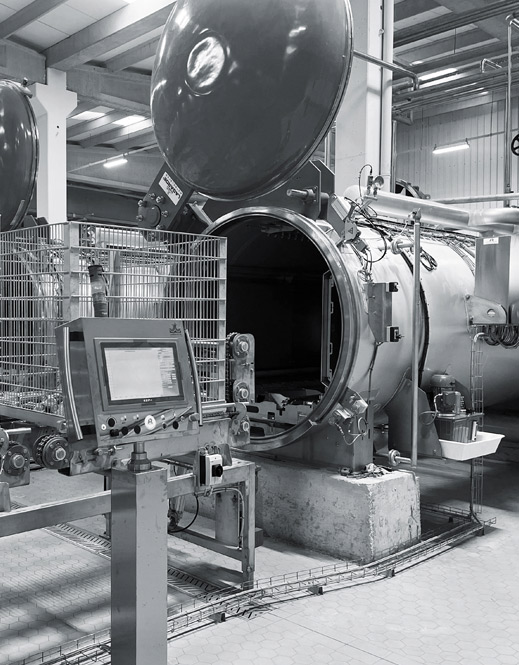

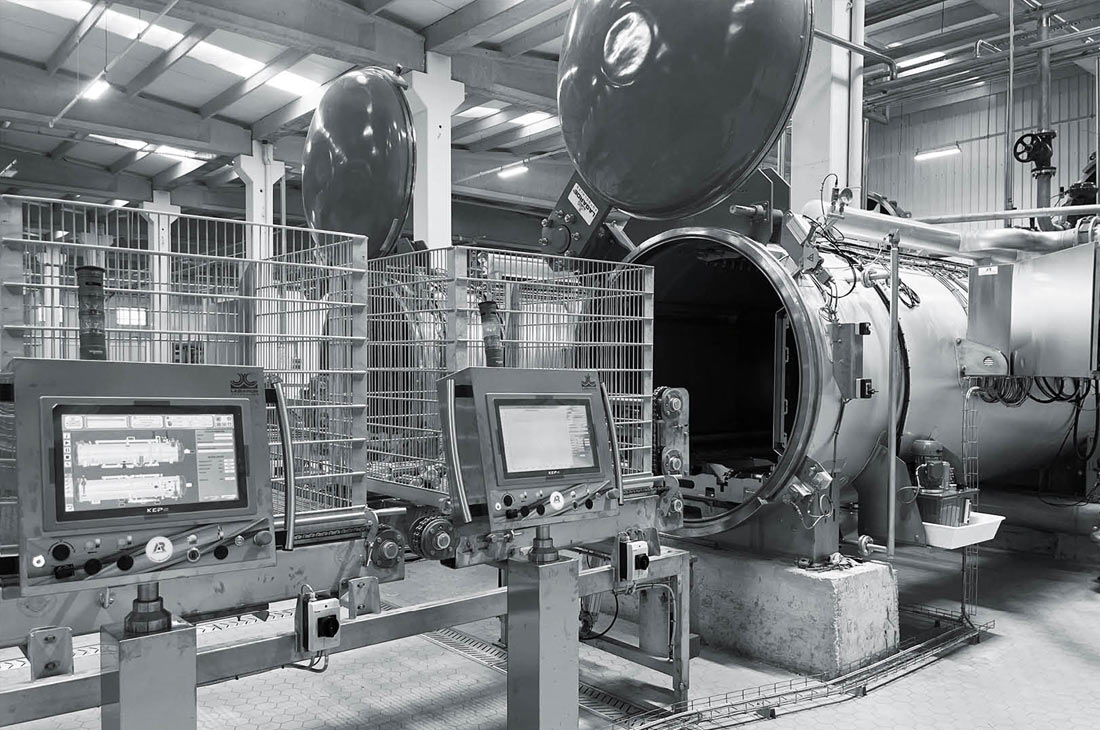

Machines for every production line

We focus on heat treatment in all its aspects, as well as alternative disinfection methods involving microbiological reduction. We also offer solutions for cooling after sterilisation or pasteurisation. We supply both static and rotating autoclaves, proven technology with a high level of standardisation but with flexible customisation possibilities. Our projects range from manual and semi-automatic to fully automated production lines. We provide in-container solutions as well as solutions for the thermal treatment of bulk products, such as blanchers, cookers, coolers, and steamers. Thanks to our extensive expertise, all our machines seamlessly connect within the production line.

TPS Knowledge Base

We provide our customers with a knowledge base containing all relevant information for the operational continuity of thermal processes. This knowledge base is consistently updated with accurate information about your machinery and its operation.

TPS Project Management

By being involved early in the development and construction of the production line or installation, TPS simplifies the final installation and prevents costly adjustments later on. Thanks to our knowledge and the ability to develop projects in 3D and as P&ID schematics at an early stage, a clear overview can be created. If desired, TPS can oversee the entire project so that you can continue focusing on your production activities.

TPS (Post) Commissioning Service

With the TPS Commissioning Service, the transition from setting up and connecting the machines to a fully functional and, where possible, automated production line is fully supported. Even after commissioning, TPS offers a smooth transition to full production. During the Post-Commissioning Service, we pay attention to all aspects relevant to implementation that have not been addressed during the startup and development phases of the production lines. Process optimisation is part of this service.

TPS On-Site Support and Service

During the startup of the production process,

our technicians support you in ensuring optimal performance. We also provide long-term services for thermal process solutions, allowing you to produce worry-free. Our solutions are designed for long-term durability and cost-effective maintenance.

TPS Service Support

We offer preventive maintenance services to

prevent machines and production lines from coming to a halt. These preventive maintenance include the replacement of parts in a timely manner. Because this service can be scheduled, it is highly efficient. Additionally, with TPS Service Support, we provide a parts-replacement service. With many parts in stock, we can respond quickly and minimise downtime.

TPS Consultancy Pilot Plant

Our customers can use our fully equipped industrial-

scale test facility. Together with our engineers, the commercial feasibility and quality of our customers’ products are tested. With this test facility, we optimise the production process down to the smallest detail and provide complete insight into energy consumption. Providing consultancy services to assess and evaluate your thermal processes for energy efficiency, consistent product quality, and process optimisation is an integral aspect of our service offerings.

TPS Training Programs

With our comprehensive operator training programmes developed by us, errors are prevented, and machines are operated correctly. This also contributes to extending the lifespan of the machines. These training programmes can be taken at our facility in Belgium or on-site. The training programmes can be supported by exclusive instructional videos provided to our customers. Refresh training sessions are also offered regularly to keep knowledge up to date.

Contact us for more information

We are delighted to share our experience with our customers

To gather knowledge, we have our own innovation hub where we test the latest possibilities to achieve effective pasteurization or sterilization while considering taste, quality, and minimizing energy and water consumption. We are happy to share our knowledge with you to create the best solution in thermal processing.